TECHNICAL: Brian K. Jeppsen, VP - R&D

(208) 766-4777 x111 • brian@hesspumice.com

SALES: Jason Kimberling, Sales Manager

(208) 766-4777 x142 • salesmgr@hesspumice.com

Flatline ASR for Pennies a Yard

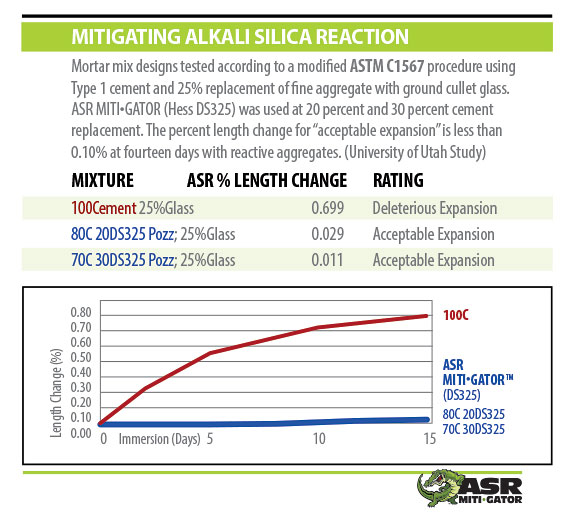

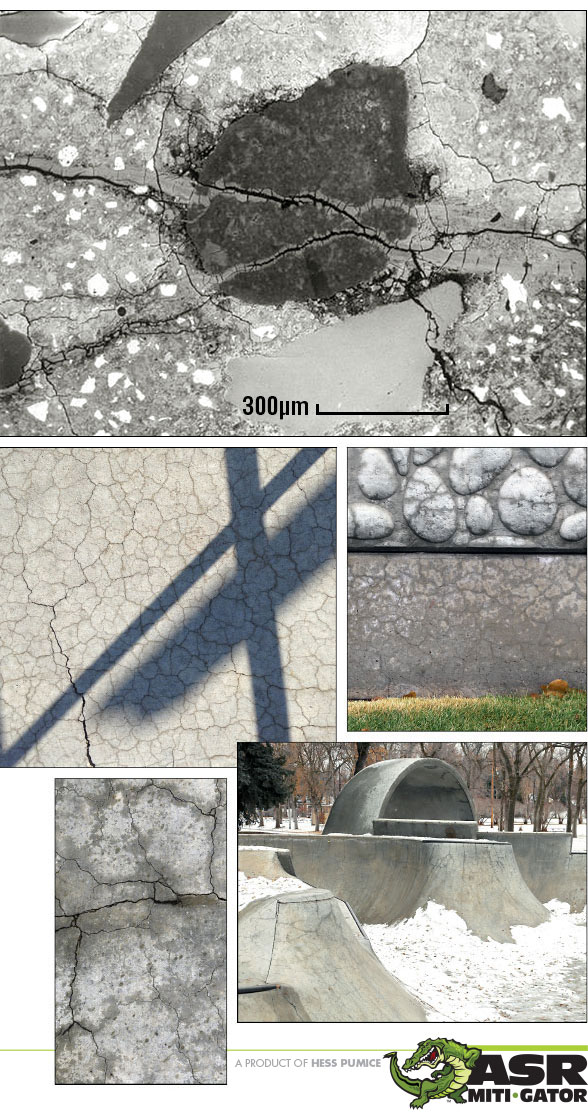

In regions of the world with reactive aggregate, Alkali-Silica Reaction (ASR) is a relentless infrastructure assassin. If the seeds of ASR—reactive aggregate and Portland cement spawned calcium hydroxide—are present in cured concrete, that concrete structure will not survive to the end of its engineered lifespan. There is no way to stop ASR once such chemically-flawed concrete is placed; no way to contain the slow-motion explosion that map-cracks the concrete—even the aggregate—and destroys its structural integrity. [MORE]

That test-data graph above talks big. But it’s backed up with ASTM standards-research providing definitive data that Hess’ ASR Miti•Gator™ will mitigate or eliminate the alkali-silica reaction in curing concrete in the presence of even the most reactive aggregate. And that “pennies a yard” claim? It’s calculated by combining the savings from using less Portland cement with the attractive cost of the ASR Miti•Gator™ replacement. [MORE]